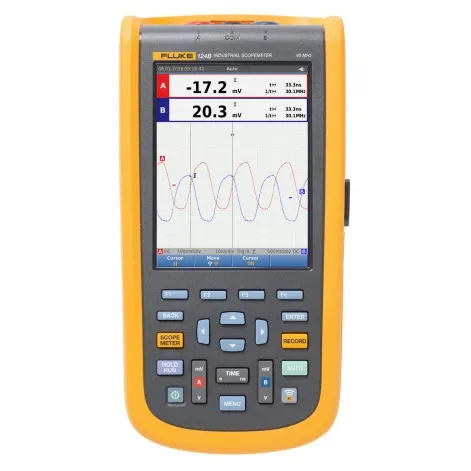

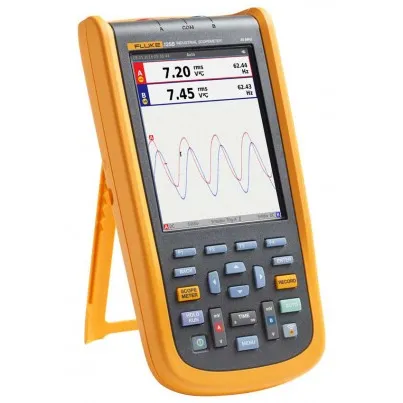

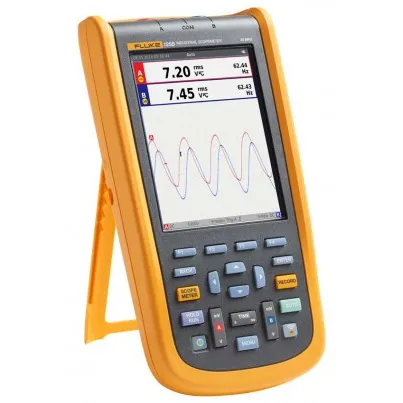

Fluke 125B/S Industrial ScopeMeter Hand-Held Oscilloscope with AC clamp and Fluke View software, 40 MHz

Work with confidence with the oscilloscope that offers simplified testing, more insight, faster electro-mechanical troubleshooting, and comes with 40 MHz of bandwidth. Conveniently measures voltage, current, power waveforms and comes with the Fluke View software.

View all

$ 3865.99

Description

Fluke 125B/S OffersCompact and rugged, this oscilloscope is ideal for industrial electrical and electro-mechanical equipment troubleshooting and maintenance applications. Features innovative functions that help technicians troubleshoot faster for quicker results and to keep their systems running smoothly. Additionally, triggering displays waveforms without having to adjust amplitude, timebase, and trigger settings. Features Key measurements: Voltage, current and power waveforms with numerical values including harmonics, resistance, diode, continuity and capacitance measurements Automatically capture, view and analyze complex waveforms: Fluke Connect and View™ triggering automatically displays waveforms without having to adjust amplitude, timebase and trigger settings, while Intellaset™ technology analyzes the signal and automatically displays critical numerical readings, making troubleshooting faster than ever View data locally on the instrument, or via Fluke Connect mobile app Dual-input digital oscilloscope and multimeter 40 MHz oscilloscope bandwidth Two 5000-count true-rms digital multimeters Connect-and-View trigger simplicity for hands-off operation IntellaSet technology automatically and intelligently adjusts numerical readout based on the measured signal Dual-input waveform and meter reading recorder for trending data over extended periods Recorder Event Detect captures elusive intermittent signals on repetitive waveforms up to 4 kHz Shielded test leads for oscilloscope, resistance and continuity measurements Resistance, continuity, diode and capacitance meter measurements Power measurements (W, VA, VAR, PF, DPF, Hz) Voltage, current and power harmonics Check Industrial networks with BusHealth physical layer tests against defined reference levels Save or recall data and instrument setups Store instrument setups defined by a test sequence for routine maintenance or most often used test procedures External optically isolated USB interface to transfer, archive and analyze scope or meter data Optional WiFi adapter connected to internal USB port to wirelessly transfer information to the PC, laptop or Fluke Connect mobile app FlukeView ScopeMeter Software for Windows Rugged design to withstand 3 g Vibration, 30 g shock, and rated IP51 according to EN/IEC60529 Highest safety rating in the industry: safety rated for CAT IV 600 V Connect-and-View triggering for an instant, stable display Oscilloscope users know how difficult triggering can be. Using the wrong settings can lead to unstable waveform captures, and sometimes the wrong measurement data. This instrument's unique Connect-andView triggering technology recognizes signal patterns and automatically sets up the correct triggering to provide a stable, reliable, and repeatable display. Connect-and-View triggering is designed to work with virtually any signal, including motor drives and control signals - without adjusting parameters, or even touching a button. Signal changes are instantly recognized and settings are automatically adjusted, providing a stable display even when measuring multiple test points in quick succession. IntellaSet/AutoReading The Auto Readings function with Fluke IntellaSet technology uses proprietary algorithms to intelligently analyze the measured waveform and automatically displays the most appropriate numerical measurements on the screen, so you can get the data you need easier than ever before. As an example, when the measured waveform is a line voltage signal, the Vrms and Hz readings are automatically displayed, whereas if the measured waveform is a square wave, the Vpeak-peak, and Hz readings are automatically displayed. Using IntellaSet technology in conjunction with Connect-and-View automatic triggering you can be sure you're seeing not only the correct waveform but the appropriate numerical reading as well. All without touching a button. Industrial equipment needs a reliable power supply to operate properly, use the dual input to obtain key power measurements For single-phase or 3-phase balanced systems, the dual inputs of the Industrial ScopeMeter 120B Series can measure AC+DC RMS voltage on channel A and AC+DC RMS current on channel B. This oscilloscope can then calculate; frequency, phase angle, active power (kW), reactive power (VA or var), power factor (PF), or displacement power factor (DPF) and can also calculate the power values for a 3-phase system where all phases have equal voltage and currents. This applies to both balanced systems and resistive loads. Harmonics Measurement Harmonics are periodic distortions of voltage, current, or power sine waves. Harmonics in power distribution systems are often caused by non-linear loads such as switched-mode dc power supplies and adjustable speed motor drives. Harmonics can cause transformers, conductors, and motors to overheat. In the Harmonics function, the Test Tool measures harmonics to the 51st. Related data such as dc components, THD (Total Harmonic Distortion), and K factor are measured to provide a complete insight into the electrical state of health of your loads. One test lead to measure multiple electrical parameters High-frequency waveform, meter, capacitance, and resistance measurements as well as continuity checks are all covered by a single set of shielded test leads. No time is wasted finding or swapping leads. FlukeView® ScopeMeter Software for Windows Get more out of your ScopeMeter with FlukeView Software: Store instrument's screen copies on the PC, in color Copy screen images into your reports and documentation Capture and store waveform data from your ScopeMeter on your PC Create and archive waveform references for easy comparison Copy waveform data into your spreadsheet for detailed analysis Use cursors for parameter measurement Add user text to instrument setups and send them to the instrument for operator reference and instructions Fluke Connect mobile app compatibility Automated industrial machinery is harder than ever to troubleshoot. It's not enough to just know where you have to test, you also have to know what to look for and that can be hard without baseline measurement data or access to subject matter experts. This Fluke Connect Assets wireless system of software and wireless test tools enables technicians to reduce maintenance costs and increase uptime with accurate equipment records and maintenance data that is easy to interpret, and share. Compare and contrast test point measurement data and trends so you can better understand signal characteristics and changes over time. And, by storing maintenance data on the Fluke Cloud you can enable team members to access it from wherever and whenever they need to so you can get advice or approvals in the field and get your systems up and running faster than ever before. Use the comprehensive recorder modes to help find intermittent faults with ease The toughest faults to find are those that happen only once in a while-intermittent event. They can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Other factors, like line outages and sags or the starting and stopping of a motor, can also cause intermittent events resulting in equipment shutdowns. When these events happen, you may not be around to see them. But, your Fluke ScopeMeter Test Tool will. You can either plot the minimum and maximum peak measurement values or record the waveform trace. And, with expandable micro SD memory, recording sessions can be done for up to 14 days. This recorder is even more powerful with the addition of Recorder Event Detect, which makes detecting and logging intermittent faults easier than ever. Just set a threshold on a meter reading or scope trace and deviations are tagged as unique events. You no longer need to search through masses of data to pinpoint faults, and can quickly step from one tagged event to the next, while still having access to the full data set. Industrial Bus Health Test verifies electrical signal quality on industrial buses Bus Health Test analyzes the electrical signals on the industrial bus or network and gives a clear "Good", "Weak" or "Bad" indication mark for each of the relevant parameters, presented next to the actual measurement value. Measured values are compared to standard values based on the selected bus types (CAN-bus, Profi-bus, Foundation Field, RS-232, and many more), or, unique reference values can be set if different tolerances are required. This oscilloscope can validate the quality of the electrical signals as soon as they are passed along the network, without looking at the data content. Additionally, this oscilloscope checks the signal levels and speed, transition times and distortion, and compares these to the appropriate standards to help you find errors such as improper cable connections, bad contacts, incorrect grounding, or improper terminators. Applications Ideal for industrial electrical and electro-mechanical equipment troubleshooting and maintenance applications

Downloads

Specifications

- A, -A, B, -B

- Normal: Captures up to 25 ns glitches and displays analog-like persistence waveform Smooth: Suppresses noise from a waveform Glitch off: Does not capture glitches between samples Envelope: Records and displays the minimum and maximum of waveforms over time

- Direct, with test leads, or with VP41 probe: 600 Vrms CAT IV, 750 Vrms maximum voltage With BB120: 600 Vrms

- Direct on input or with leads: 600 Vrms CAT IV for derating With banana-to BNC adapter BB120: 600 Vrms for derating Maximum floating voltage from any terminal to ground: 600 Vrms CAT IV, 750 Vrms up to 400 Hz

- Configurations: 1 phase/3 phase 3 conductor balanced loads (3 phase: fundamental component only, AUTOSET mode only) Power factor (PF): Ratio between watts and VA range - 0.00 to 1.00 Watt: RMS reading of multiplying corresponding samples of input A (volts) and input B (amperes); Full scale reading: 999 counts VA: Vrms x Arms; Full scale reading: 999 counts VA reactive (var): √((VA)2-W2); Full scale reading: 999 counts

- External: Via power adapter BC430 Input voltage: 10 to 21 V DC Consumption: 5 W typical Input connector: 5 mm jack Internal: Via battery pack BP290 Battery power: Rechargeable Li-Ion 10.8 V Operating time: 7 hours with 50 % backlight brightness Charging time: 4 hours with test tool off, 7 hours with test tool on Allowable ambient temperature: 32 to 104°F (0 to 40°C) during charging

LEGAL DISCLAIMER

All products are 100% genuine and legally purchased from authorized sources. Indspare is not an authorized dealer, agent or affiliate of any of the designers, brands, or manufacturers, the products of which are offered for sale on www.indspare.com. All trademarks, brand names, and logos mentioned are used for identification purposes only and are registered trademarks of their respective owners who reserve the rights of ownership. The use of trademark, brand name or product on our website is not intended to suggest that the company, trademark or brand is affiliated to or endorses our website.