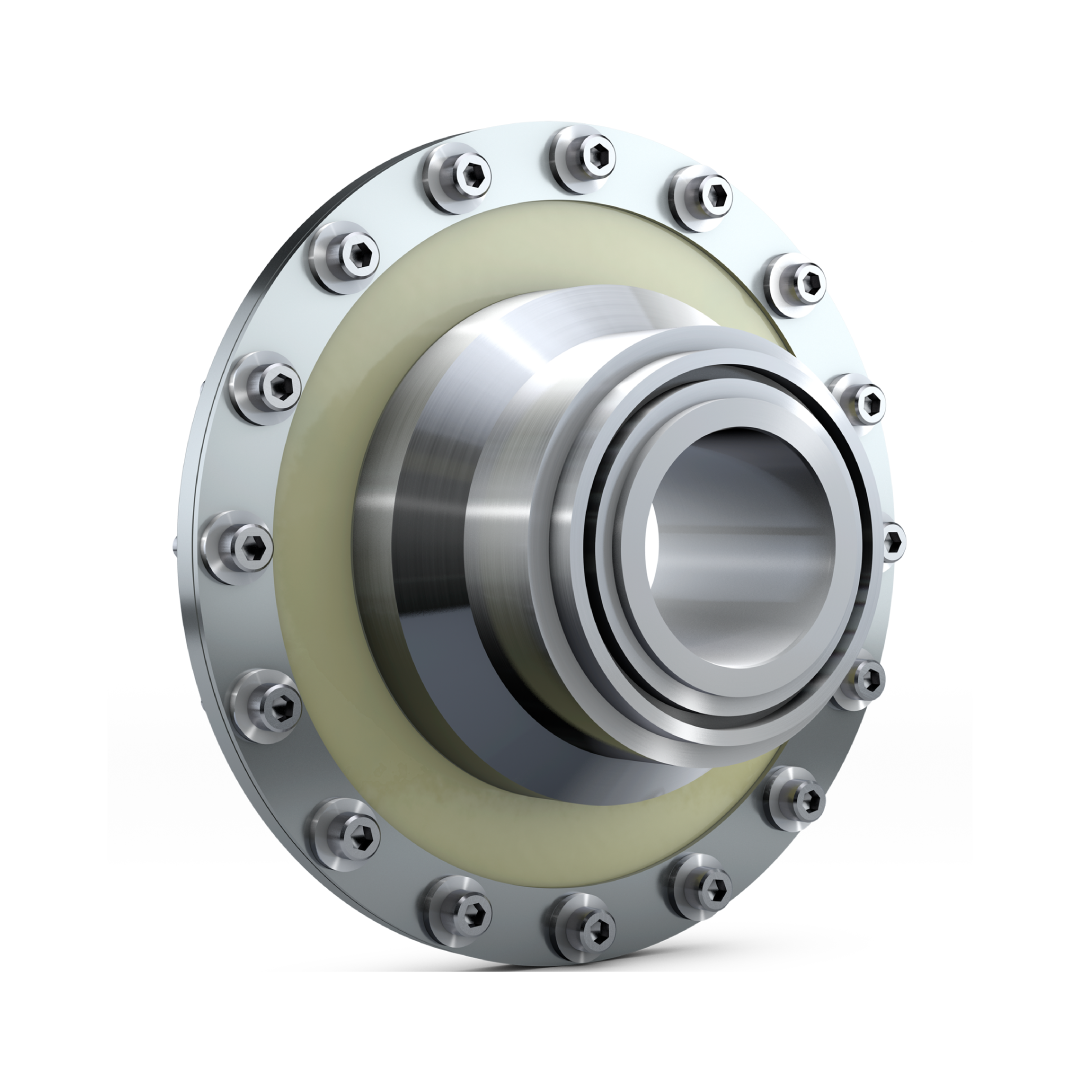

Rexnord Euroflex Disc Couplings

As part of the Rexnord Coupling portfolio, high-performance Rexnord Euroflex Disc Couplings are uniquely designed and manufactured for each and every application they encounter, providing the customer advantage of a high-performance coupling, competitive in design with traditional coupling suppliers, and an economical solution.

View all

Description

Rexnord Euroflex Disc Couplings are uniquely designed and manufactured for each application, providing high-performance solutions competitive with traditional coupling suppliers. They are ideal for test bench, gas and steam turbine-driven, and gas compression applications, offering high torque and speed capacity with a low-mass solution. Each coupling is torsionally tuned to fit the specific design requirements, with speeds in excess of 30,000 rpm. These couplings support up to 120,000 hp (90 megawatts). Euroflex Disc Couplings are highly customized and optimized for gas turbines, steam turbines, and compressor applications. Capable of handling torque capacities exceeding 17 million in-lbs (2,000,000 Nm) and speeds above 30,000 RPM. Applications include power generators, compressors, and test benches in industries like LNG, oil & gas, and power generation. Engineered-to-order designs ensure compliance with API 671, ISO 10441, and ATEX standards.

Features & Benefits

• Ideal for test bench, gas and steam turbine-driven, and gas compression applications • High torque and speed capacity with low-mass solution • Torsionally tuned to fit your complete design • Torque capacities greater than 17 million in-lbs (2,000,000 Nm) • Speeds in excess of 30,000 rpm • Supports 120,000 hp (90 megawatts) and meets API 671, ISO 10441, ATEX, DNV, and ABS specifications) • ISO 9001-2008 certifiedTest bench applications

• Turbine to gearbox: 670 hp (500 kW) at 50,000 rpm with an overall length of 10.40 inches (264 mm) • Turbine to gearbox: 536 hp (400 kW) at 45,000 rpm with an overall length of 4.72 inches (120 mm) • Race car: 2,681 hp (2,000 kW) at 28,000 rpm; combination of titanium, aluminum and alloy steel to meet the weight requirements of 9.25 pounds (4.2 kg), over 50 percent lighter than a traditional test bench couplingCompressor applications

• Pipeline compressor: gas turbine to compressor, 38,874 hp (29,000 kW) at 7,700 rpm • Purified Terephthalic Acid (PTA) plant: steam turbine to compressor, 71,662 hp (53,460 kW) at 3,021 rpm • LNG ship: gearbox to compressor, 22,015 hp (16,423 kW) at 8,242 rpmSteam turbine-driven applications

• Pipeline: steam turbine to generator, 160,858 hp (120,000 kW) at 3,000 rpm • Petrochemical refinery: steam turbine to compressor, 69,705 hp (52,000 kW) at 3,021 rpm • FPSO ship: steam turbine to compressor, 10,295 hp (7,680 kW) at 12,075 rpmGas turbine applications

• Fertilizer plant: gas turbine to compressor, 23,767 hp (17,730 kW) at 10,973 rpm • Floating production, storage and off-loading (FPSO) ship: gas turbine to generator, 30,161 hp (22,500 kW) at 13,192 rpm • Liquefied natural gas (LNG) upstream facility: gas turbine to gearbox, 18,633 hp (13,900 kW) at 9,500 rpmDownloads

Specifications

LEGAL DISCLAIMER

All products are 100% genuine and legally purchased from authorized sources. Indspare is not an authorized dealer, agent or affiliate of any of the designers, brands, or manufacturers, the products of which are offered for sale on www.indspare.com. All trademarks, brand names, and logos mentioned are used for identification purposes only and are registered trademarks of their respective owners who reserve the rights of ownership. The use of trademark, brand name or product on our website is not intended to suggest that the company, trademark or brand is affiliated to or endorses our website.