Siemens SITRANS Probe LU240 Ultrasonic Level Transmitter for Level, Volume and Volume Flow Measurements, 2" Male NPT Connection, 4…20 mA signal, HART Protocol, Pressure range -0.2...0.5 bar, 7ML51101DD074CF3-Z-E33

SITRANS Probe LU240 Ultrasonic level transmitter ideal for level, volume, and volume flow measurements. It works with liquids, slurries, and bulk materials up to 12 m (40 ft).

View all

KWD 350.000

Description

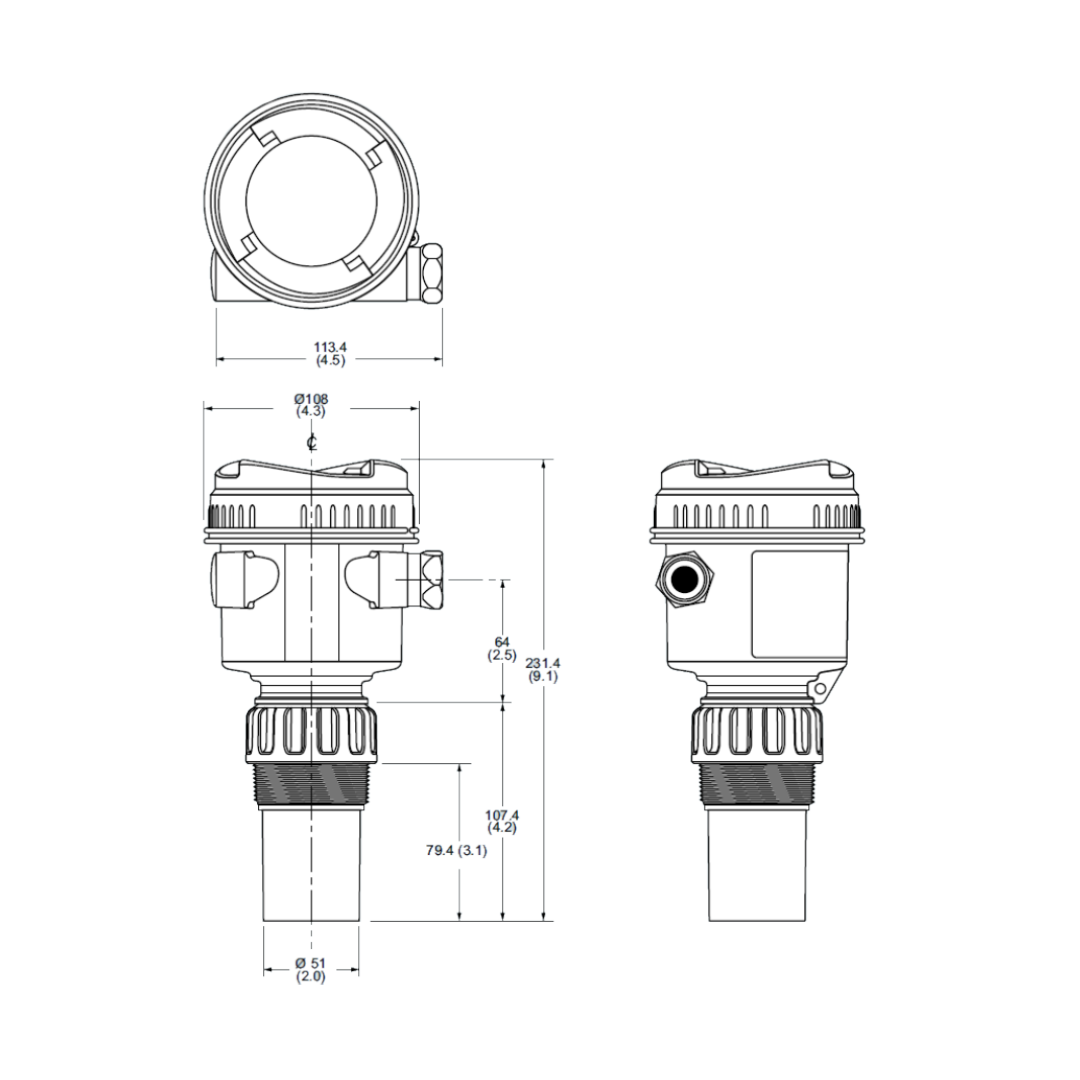

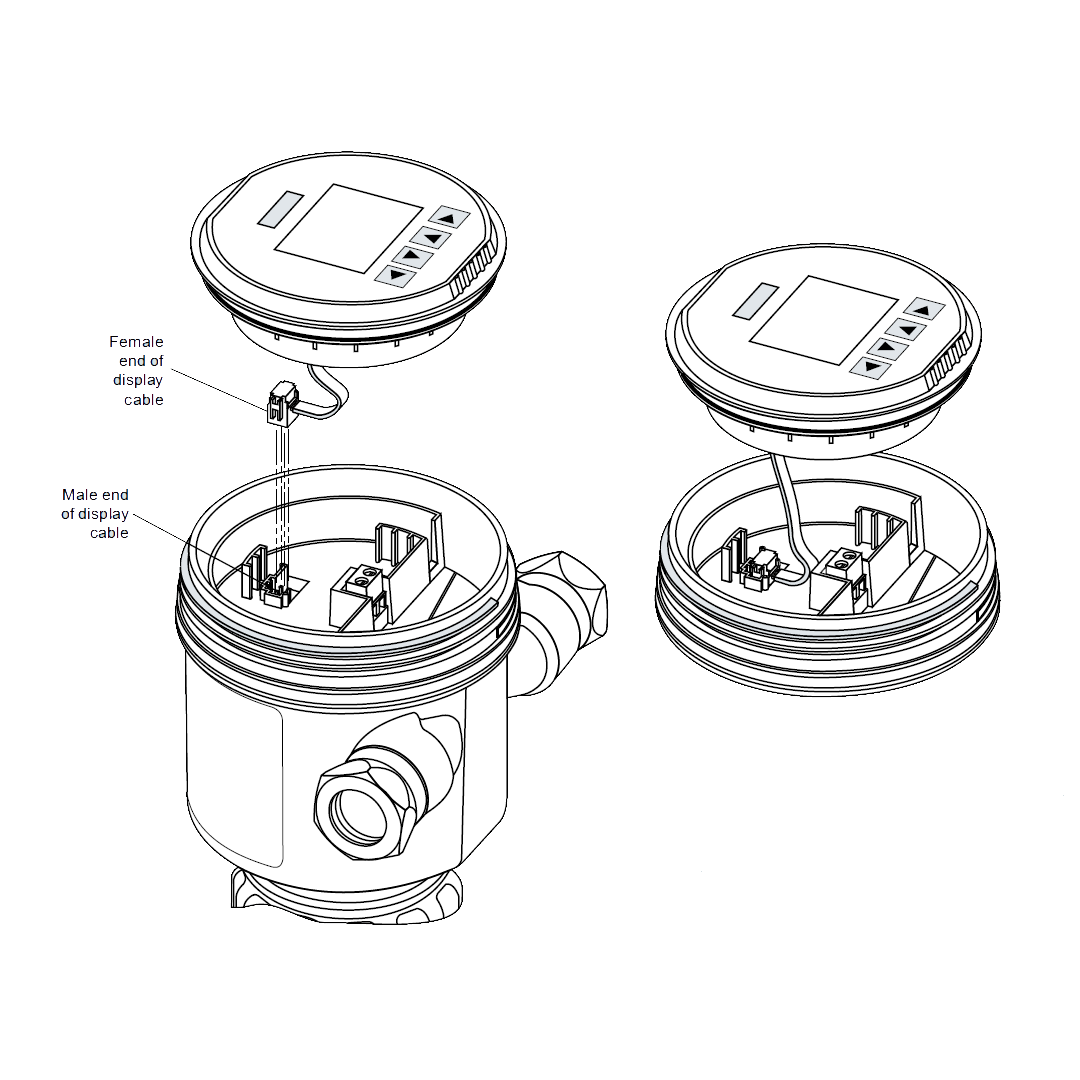

Siemens SITRANS Probe LU240 Ultrasonic level transmitter ideal for level, volume, and volume flow measurements. It works with liquids, slurries, and bulk materials up to 12 m (40 ft). Communications: HART (4 ... 20 mA) level, volume, volume flow Ingress protection: IP66, IP68, TYPE 4X, 6 Measurement range/ wetted parts: 200 ... 6000 mm (7.87 ... 236.22 inch), PVDF Copolymer Process connection: 2" NPT [(Taper), ASME B1.20.1] . Non wetted parts: Plastic (PBT/PC material) Enclosure,Type of protection : Atex/IEC Ex Ex I (ia) CSA/FM (Class 1, Div 1/Zone 0) IS / FM NI (Class 1, Div 2) Electrical connections/ cable entries: 2 x M20 x 1.5 (one general purpose Polyamide cable gland and one Polyamide blocking plug provided) Local HMI: With display (clear lid of PC material, Approvals: NEPSI, IECEx - Ex ia IIC T4 Ga. The ultrasonic level transmitter for all level, volume and volume flow demands and every challenging environment.

Key Features

• Non-Contact Ultrasonic Technology: Ensures accurate level measurement without direct contact with the medium.

• Compact and Rugged Design: Suitable for harsh industrial environments with IP68 protection.

• Plug-and-Play Configuration: Easy installation with minimal setup time and effort.

• Wide Application Range: Ideal for liquids, slurries, and solids in tanks and open channels.

• Advanced Signal Processing: Reduces false echoes and enhances measurement reliability.

• Integrated Display: Provides local readout and user-friendly interface for configuration.

• HART Communication: Enables seamless integration with existing control systems.

Applications

• Water and wastewater treatment plants

• Chemical storage and processing tanks

• Food and beverage production facilities

• Open channel flow monitoring

• Level measurement in slurries and solids

• Industrial storage silos and vessels

• Remote and hard-to-access level measurement points

Benefits

• Non-contact measurement reduces maintenance and wear

• Highly accurate level monitoring improves process control

• Compact design fits in tight or space-constrained areas

• Fast installation and easy configuration saves time

• Robust design ensures long-term reliability in harsh environments

• Versatile use across multiple industries and applications

• Seamless integration with existing control systems via HART communication

Specifications

LEGAL DISCLAIMER

All products are 100% genuine and legally purchased from authorized sources. Indspare is not an authorized dealer, agent or affiliate of any of the designers, brands, or manufacturers, the products of which are offered for sale on www.indspare.com. All trademarks, brand names, and logos mentioned are used for identification purposes only and are registered trademarks of their respective owners who reserve the rights of ownership. The use of trademark, brand name or product on our website is not intended to suggest that the company, trademark or brand is affiliated to or endorses our website.