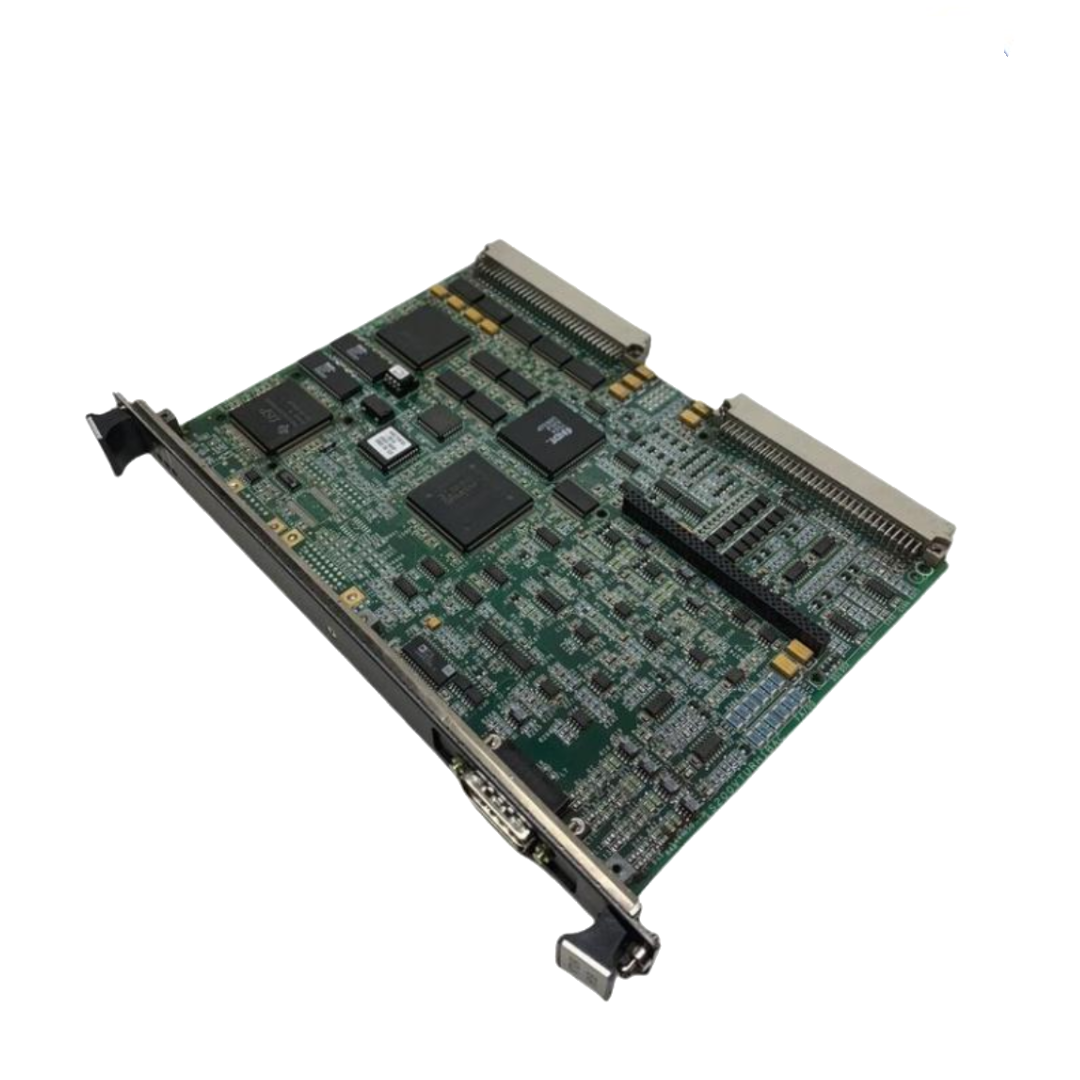

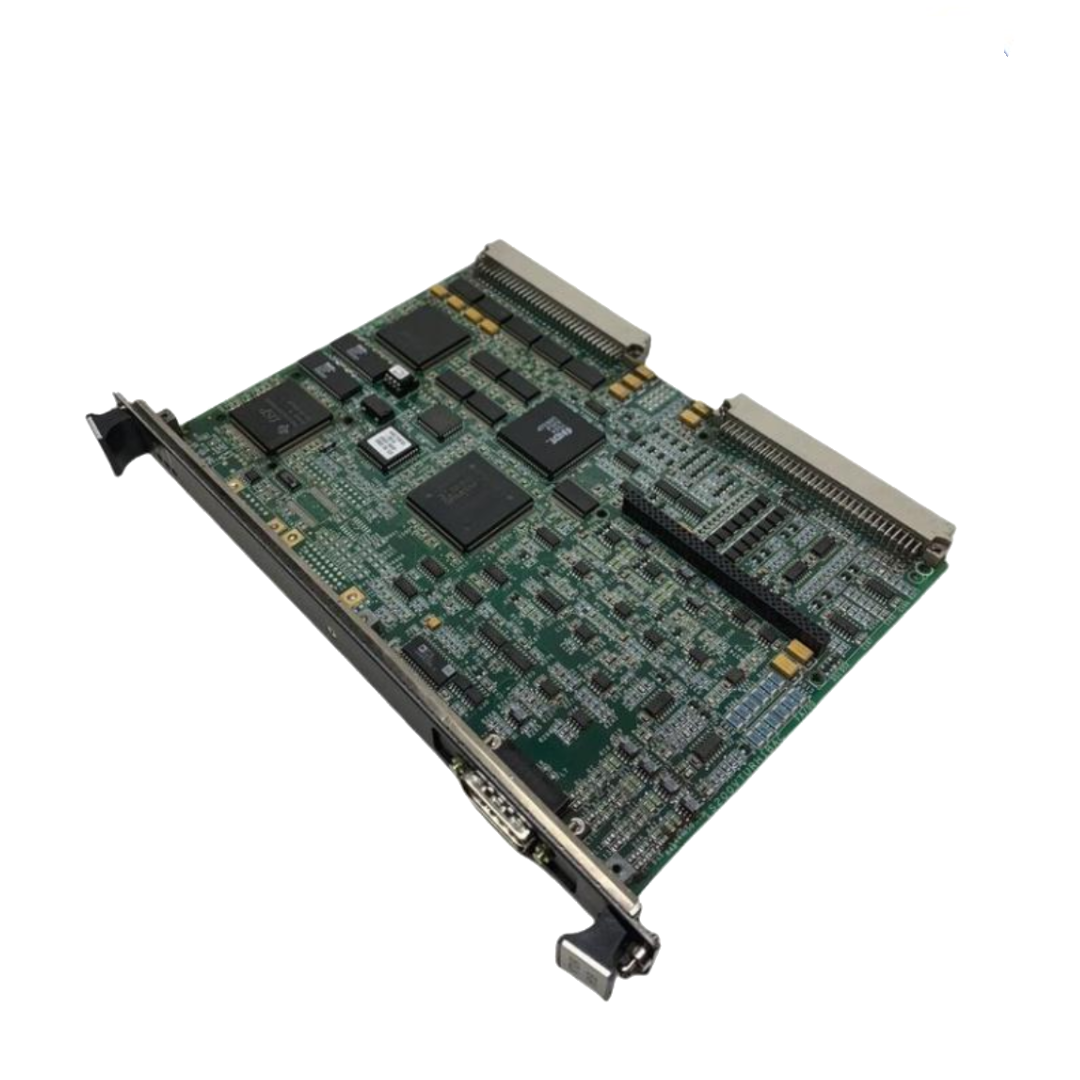

General Electric, Speedtronic Mark VI Series, VME Primary Turbine Protection Card, IS200VTURH1B

IS200VTURH1B is a VME Primary Turbine Protection Board developed by GE. The board monitors shaft current/voltage (with alarms for excessive levels), measures turbine speed to generate the primary Overspeed trip, and controls the three primary Overspeed trip relays on the TRPx terminal board. The board also monitors eight Geiger-Mueller flame detectors. IS200VTURH1B - VME Primary Turbine Protection Card is available in brand new, Unused and Refurbished Condition and also Repairable.

View all

KWD 2,325.000

Description

The IS200VTURH1B MKVI is not just any turbine generator—it’s a meticulously engineered system designed to meet the ever-growing demand for efficient and reliable power generation. At its core lies an axial-flow, single-stage, impulse turbine that expertly converts high-pressure, high-temperature steam into mechanical power. This mechanical power drives a synchronous, brushless generator, producing electricity that powers industries and communities alike.The turbine’s design is nothing short of ingenious, featuring a carefully crafted flow path that optimizes the conversion of steam energy into rotational force. This design, coupled with advanced aerodynamic profiling, ensures that the turbine operates at peak efficiency, extracting every ounce of energy from the incoming steam. The generator component of the IS200VTURH1B MKVI is equally impressive, boasting a robust, four-pole synchronous machine with a brushless excitation system. This design not only enhances reliability but also reduces maintenance requirements and improves overall system efficiency. Additionally, the generator’s hydrogen-cooled stator and water-cooled rotor further elevate its performance and durability, ensuring uninterrupted power generation.

Features

- High-Efficiency Turbine Design: The single-stage impulse Design and optimized flow path ensure maximum energy extraction from incoming steam, resulting in higher power output and reduced fuel consumption. - Robust Synchronous Generator: The brushless excitation system enhances reliability, while The hydrogen-cooled stator and water-cooled rotor improve performance and durability. - Advanced Control and Monitoring system: Precise Control of The Turbine-Generator unit is achieved through a state-of-The-art system that continuously monitors parameters like vibration, temperature, and pressure, adjusting operation for optimal performance and reliability. - Modular Design: Easy installation, maintenance, and upgrades are facilitated by The unit’s Modular Design, providing flexibility for power plant operators. - Comprehensive Instrumentation and Diagnostics: vibration sensors, temperature monitors, and pressure transducers offer real-time data on unit performance, enabling proactive maintenance and early issue detection.Benefits

- Improved Efficiency and performance: higher power output, reduced fuel consumption, and lower operating costs result from The turbine’s High-Efficiency design.

- Enhanced reliability and Durability: Exceptional reliability, reduced maintenance requirements, and increased uptime are achieved through Robust construction and Advanced Control systems.

- reduced Environmental Impact: lower fuel consumption and optimized emissions contribute to a more sustainable approach to power generation.

- increased Operational flexibility: Compatibility with various steam conditions and a Modular Design allow for greater Operational flexibility, enabling adaptation to changing requirements.

- Improved maintenance and Serviceability: Simplified maintenance procedures and Comprehensive Instrumentation minimize downtime and maintenance costs, ensuring efficient servicing when needed.

Applications

- Baseload Power Plants: Ideal for large-scale baseload power generation, providing consistent energy output.

- Cogeneration Facilities: Compatible with simultaneous electricity and thermal energy production, enhancing overall system efficiency.

- Combined Cycle Power Plants: Seamlessly integrated into combined cycle plants to further optimize energy generation.

- Industrial Power Generation: Reliable power source for industrial facilities requiring consistent and uninterrupted energy supply.

- Peaking Power Plants: Rapid start-up capabilities make it suitable for peaking power plants, meeting sudden spikes in electricity demand.

Refurbishing

Proper refurbishing of the IS200VTURH1B circuit board can increase its longevity.

- The refurbishing process includes,

- Replacing all aging and commonly failing components.

- Applying TIL modification if there is any

- Reflowing solder to eliminate dry solder.

-Thorough Industrial standard cleaning of the card.

- Applying a protective coating, etc.

Functional Verification Test

We carry out the FUNCTIONAL VERIFICATION TEST of IS200VTURH1B in an actual OEM system setup. Because of using the OEM system, we can assure 100% reliability. Like any other card, all inputs and outputs will be individually verified for their functionality. So every channel is individually verified. Depending on the board, we do load testing to ensure the proper stability of the board.Specifications

LEGAL DISCLAIMER

All products are 100% genuine and legally purchased from authorized sources. Indspare is not an authorized dealer, agent or affiliate of any of the designers, brands, or manufacturers, the products of which are offered for sale on www.indspare.com. All trademarks, brand names, and logos mentioned are used for identification purposes only and are registered trademarks of their respective owners who reserve the rights of ownership. The use of trademark, brand name or product on our website is not intended to suggest that the company, trademark or brand is affiliated to or endorses our website.