Airtac SC Series Tie-Rod Type Pneumatic Cylinder, Double Acting with 80 mm Bore and 125 mm Stroke with magnet, SC80X125S

Airtac Standard tie-rod pneumatic cylinder double acting 80mm bore 125 mm stroke with magnet and Thermoplastic Poluurethene(TPU) seal material.

View all

KWD 29.300

Description

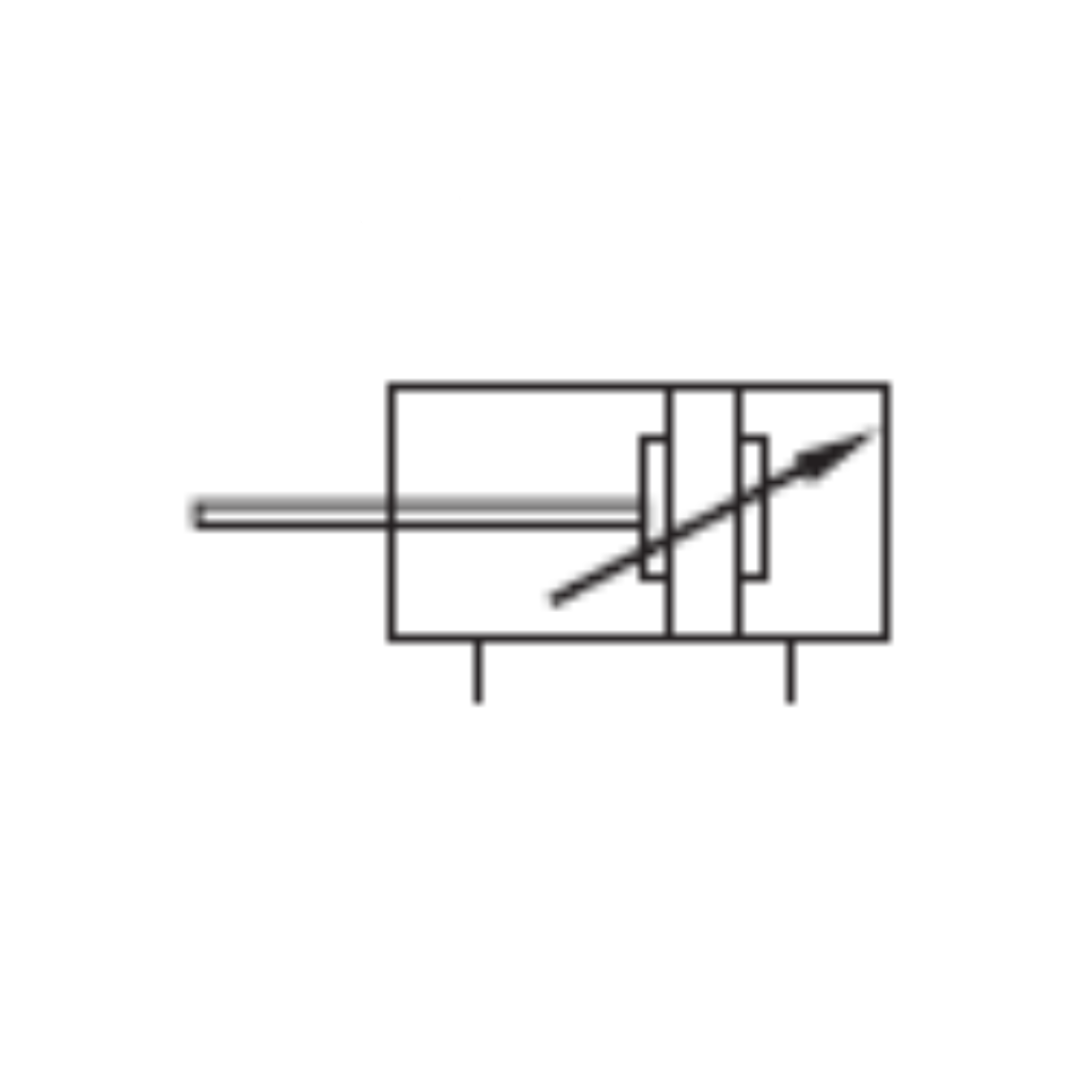

The Airtac SC80X125S is a double-acting standard air cylinder developed by Airtac International Group, a renowned global manufacturer specializing in pneumatic equipment. Designed for robust and high-performance industrial automation, this pneumatic cylinder is part of the SC Series, which follows ISO 15552 standard specifications. It features an 80mm bore size and a 125mm stroke, offering reliable and consistent force output for various industrial tasks. Engineered with high-quality aluminum alloy for both the cylinder tube and end covers, the SC80X125S ensures excellent corrosion resistance and durability in harsh environments. Its double-acting mechanism provides precise motion control in both directions, making it ideal for applications that require accurate reciprocating motion such as in packaging machines, automation systems, assembly lines, and material handling equipment.

Features

• Standard cylinder manufactured by Airtac.

• The seal of piston adopts heterogeneous two way seal structure. It's dimension is tight and it has the function of grease reservation.

• It is tie rod cylinder. The cylinder barrel and front/rear cap is jointed by tie rods with high reliability.

• Compared with ISO15552 standard cylinder SC series cylinder with the same bore size is shorter.

• The buffer adjustment of cylinder is smooth and steady. • Cylinders and mounting accessories with several specifications are optional.

• The seal material with high temperature resistance is adopted to guarantee the normal operation of cylinder at 150 degrees celsius.

Installation and Application

• When load changes in the work, the cylinder with abundant output capacity shall be ed.

• Relative cylinder with high temperature resistance or corrosion resistance shall be chosen under the condition of high temperature or corrosion.

• Necessary protection measure shall be taken in the environment with higher humidity, much dust or water drops, oil dust and welding dregs.

• Dirty substances in the pipe must be eliminated before cylinder is connected with pipeline to prevent the entrance of particles into the cylinder.

• The medium used by cylinder shall be filtered to 40?m or below.

• Anti-freezing measure shall be adopted under low temperature environment to prevent moisture freezing.

• The cylinder shall be carried out test run without load before application. Prior to run, buffer shall be turned to the minimum and gradually released to avoid the damage on cylinder caused by excessive impact.

• The cylinder shall avoid the influence of side load in operation to maintain the normal work of cylinder and extend the service life.

• If the cylinder is dismantled and stored for a long time, please conduct anti-rust treatment to the surface. Anti-dust caps shall be added in air inlet and outlet ports.

Downloads

Specifications

LEGAL DISCLAIMER

All products are 100% genuine and legally purchased from authorized sources. Indspare is not an authorized dealer, agent or affiliate of any of the designers, brands, or manufacturers, the products of which are offered for sale on www.indspare.com. All trademarks, brand names, and logos mentioned are used for identification purposes only and are registered trademarks of their respective owners who reserve the rights of ownership. The use of trademark, brand name or product on our website is not intended to suggest that the company, trademark or brand is affiliated to or endorses our website.